Nitrogen+Syngas published an article on data-driven chemical process optimization.

Recently, Nitrogen+Syngas published an article about the growing importance of technical services for chemical producers in their May-June 2020 issue. The article explains which new digital tools and services are available and how data-driven chemical process optimization by Navigance delivers value to customers operations. Learn more about it and download the article from the link above.

Nitrogen+Syngas is the magazine for the nitrogen and syngas industries, which is released bi-monthly by BCInsight Ltd. More information regarding the magazine can be found here.

Preview

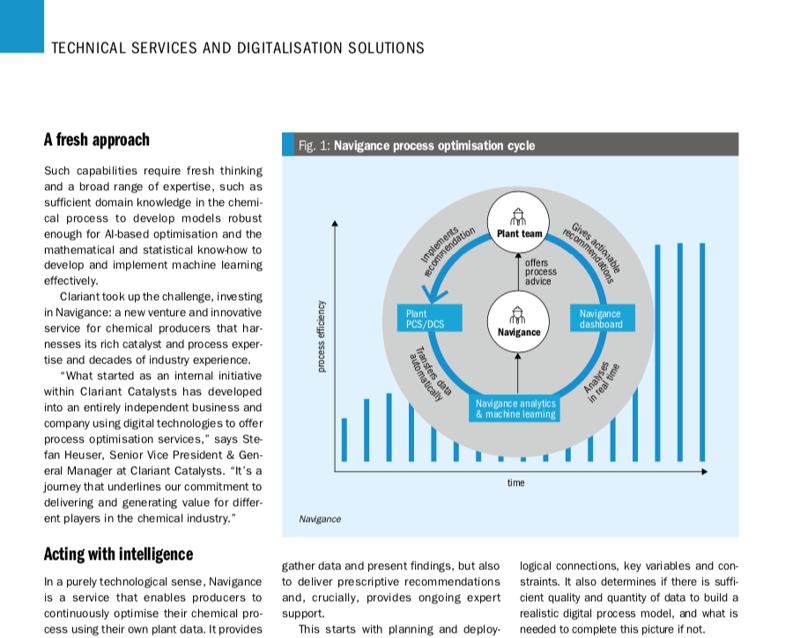

Navigance is a tech startup recently created by Clariant: a cloud-based solution providing real-time recommendations to optimize control parameters in chemical processes. Its innovative approach, combining hybrid plant models and machine learning with process and catalyst expertise, can deliver continuous benefits within weeks, without tying up in-house resources.

Fine tuning a chemical process such as methanol production for optimum efficiency and reliability is an art. Keeping plant systems not only running, but running at their best, takes years of frontline experience and expertise to master. And, despite the many digital advances now within plants’ reach, it still takes a considerable amount of educated guesswork in many cases, too.

One of the key challenges for chemical facilities seeking optimization is their sheer complexity. Their many interlinked and overlaid processes and variables make it difficult to build realistic first principle plant models that describe real-time process behavior. The control systems commonly in use are also insufficient to enable dynamic, non-linear process optimization.